Thermal insulation is an important part of commercial roofing assemblies. The aim of this article is to examine the factors influencing the thermal resistance, known as R-value of polyiso. The prediction of long term R-value and the influence of climate, i.e. temperature, have been of significant interest over the past few decades as building energy budgets have increased in importance. Recent discussions as to what R-value the designer should use and the importance of ambient temperature are reviewed and discussed.

- Polyiso foam is the most common type of insulation today, due to its high R-value per inch, fire resistant properties, and solvent resistance.

- Polyiso blocks air flow, lowering condensation risks compared to air permeable insulations.

- Polyiso's greatest value is seen during summer months when air conditioning usage is at its highest. The cost of electricity is four times as expensive as gas on an equivalent Btu basis. This makes the impact of air conditioning greater than winter heating.

Introduction

Preventing water intrusion into the built environment during precipitation has always been regarded as the basic function of the roof. However, reducing heat flow through the building enclosure is a very important secondary function. Maintaining interior thermal comfort has always been an important part of residential construction, but it wasn't until the early 1970s that the use of thermally insulated steel roof decks became commonplace in commercial construction due to the need to lower building energy costs.

Polyisocyanurate thermal insulation, commonly referred to as polyiso, has proven to be popular due to a combination of its cost effectiveness (i.e. cost per insulation unit), efficiency (i.e. insulation value per unit thickness), and fire resistance, as compared to some competitive materials. Polyiso has recently come to represent over 75% of the commercial roof insulation market. However, as polyiso has grown in popularity, so has the interest in understanding a more exacting insulation value of this material. With rising energy costs it is more important to accurately specify heating, ventilation, and air conditioning equipment (HVAC). In addition, once a building is completed, it is important that the owner/occupier be able to better anticipate future energy costs from a budgetary perspective.

How Polyiso Is Made

With any foam insulation material, the process begins with the plastic or polymer precursor materials being in the liquid phase. Gaseous blowing agent(s) is introduced either by some form of injection into the process or through chemical reactions that create the polymer matrix. Initially, the blowing agent(s) is present as an extremely fine dispersion. In the case of polyiso, pentane is used as the blowing agent and during the subsequent development of the matrix, heat is released. The heat causes the dispersed pentane to expand, forming gaseous cells. Growth of these cells ultimately results in cell impingement, the entire process being indicated schematically below:

When the cells impinge, surface tension tends to cause the material between two cells to thin, and material between multiple cells to thicken. This results in so called cell windows and struts, as indicated here:

The characteristics of the windows and struts, such as thickness, size, and number, influence the overall thermal resistance of the foam along with the blowing gas composition as discussed later.

Key characteristics of polyiso are;

- The cells are 99% closed. This means that moisture doesn't condense within polyiso and that it limits the diffusion of moisture carrying air up through the roof assembly.

- The cell material, i.e. the polymer, represents less than 5% of the total foam volume. When it's said that shipping polyiso is like shipping air, it's because 95% of the weight is the gas within the cells.

- The material is a thermoset – in a fire situation it won't melt and then drip down through openings in the roof deck. Also, it is not affected by solvents unlike some other foams such as polystyrene.

How Polyiso Insulates

There are three ways in which heat can travel through a foam material, these being conduction, convection, and radiation, as shown schematically below;

Conduction – closed cell foams, such as polyiso, consist of the polymer cells and the gas in those cells.

- The cell material, i.e. the polymer, represents less than 5% of the total foam volume and therefore, the thermal conduction of that material accounts for a very minor fraction of the total heat transfer. Furthermore, the path along the polymer from the hot side to the cold side is convoluted. Manufacturers strive for low foam density and polymer conduction can be generally considered to be negligible.

- The gaseous mixture within the cells represents more than 95% of the total foam volume. That gas phase accounts for essentially all of the thermal conduction through polyiso. The blowing agent used to create the foam will have a certain conductivity, however over time that blowing agent may diffuse out of the foam and air could diffuse in. The diffusion of gas into and out of polyiso is slower than for other polymer foams, such as those based on polystyrene.

Convection is the heat transfer due to the bulk movement of molecules within fluids such as gases and liquids, from a hot surface towards a colder surface. In foams such as polyiso, the cells are too small for any convection to occur. Also, the temperature difference across each individual cell is too small to cause convection.

Radiation – thermal energy radiates from hot surfaces and is absorbed by materials depending on their opacity and thickness. Polyiso doesn't totally block thermal radiation; cell walls are considered to be too thin to absorb thermal radiation, however cell struts are thought to absorb and then re-radiate thermal energy. Manufacturers aim to make small cells, i.e. more cells per unit volume, to be more effective at blocking thermal radiation.

Insulation's Benefit for a Roof

Insulation has two main effects on heat flux into and out of a building.

- During the summer, flux of the heat from the sun down into a building is reduced. Similarly, reflective membranes also reduce the amount of heat but do so by reflection. During the winter, insulation reduces the heat flux out from the building, thereby lowering heating costs.

- Insulation delays the flux of heat into or out of a building. Polyiso has "thermal inertia" unlike, for example, reflective membranes which do not have this effect.

- For buildings such as offices, this delaying effect is a very important benefit of insulation. It means that the maximum air conditioning effort due to heat flux through the roof is required for less hours of the day.

Specification of Thermal Resistance

Polyiso is manufactured to meet the ASTM C1289 Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board. C1289 specifies the thermal resistance at a mean temperature of 75°F for various product thicknesses and requires that the values at 40 and 110°F be made available upon request.

Important features of manufacturer's published R-values are;

- The values are an average across a temperature range. The test methods need the insulation specimen to have a hot and a cold side which are required to be at least 40°F apart. Most reputable test labs use a difference of 50°F for accuracy. So, a published value at 75°F is actually an average R-value across the range of 50 to 100°F.

- To take into account the diffusion of gas out of, and air into, foam, the values are based on projected "Long Term Thermal Resistance" or LTTR, obtained by rapidly aging thin slices of the foam.

- Beginning in 2003, the Polyisocyanurate Insulation Manufacturers Association, PIMA, established a third party certification program to independently validate LTTR values. This is referred to as the PIMA QualityMark™ program. The LTTR values are considered as "labelled R-values" to be used by building design professionals.

- Label R-values represent a 15-year time-weighted average value. They can help a design professional estimate a building's energy efficiency without having to be concerned about long term loss of performance, this being factored into the value.

Validation of Label R-values

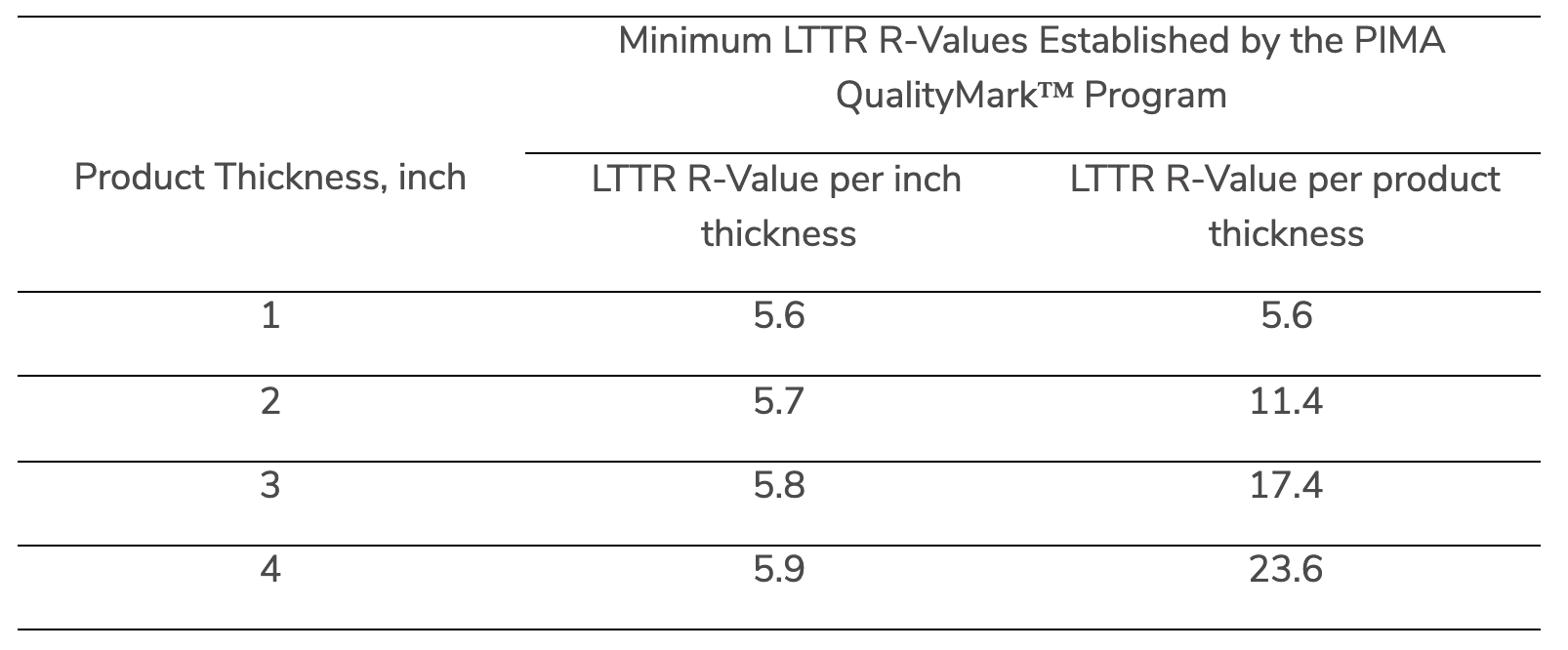

The PIMA QualityMark™ program requires participating manufacturers to meet the following R-values for the various product thicknesses.

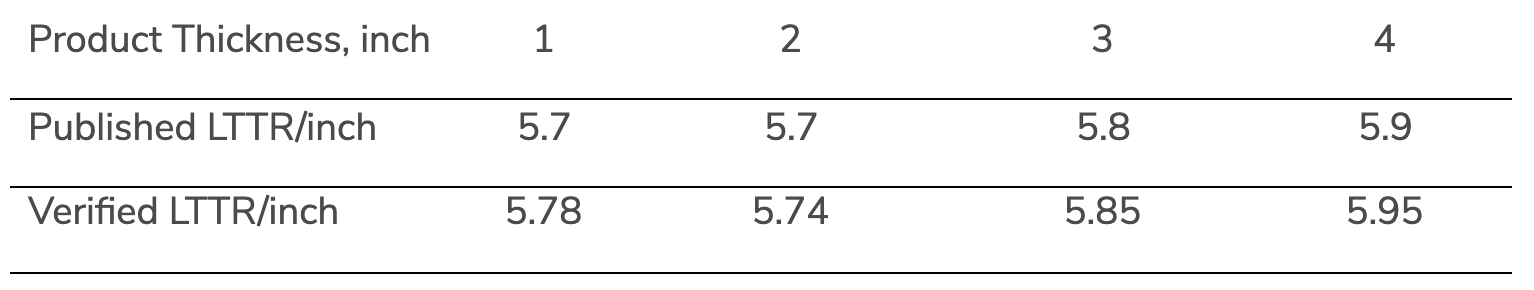

The PIMA QualityMark™ program requires each manufacturing facility to submit to an annual verification of LTTR values. During verification, independent third-party representatives visit each facility and select a minimum of five boards for testing. The overall process is administered by FM Global. The results of a 2015 PIMA QualityMark verification testing are summarized below:

A total of 33 samples were tested for each thickness at a mean temperature of 75°F. These values, obtained from a third party independent process, are reassuring especially given the large number of samples involved (33 samples x 5 specimens = 165 tests). The PIMA Quality Mark program exists to ensure that member manufacturers are held accountable to produce product meeting published label values.

R-Value and Temperature

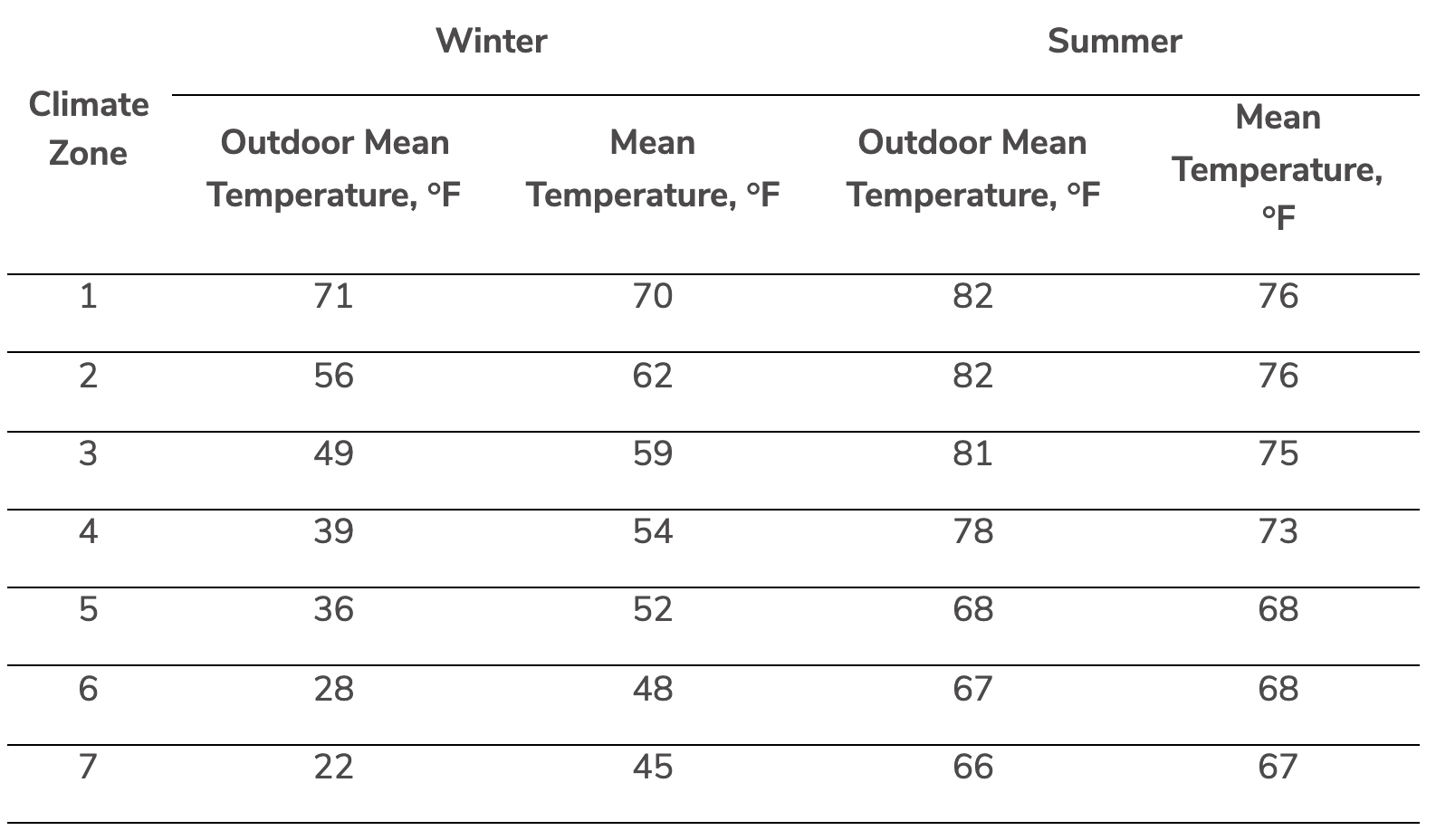

As noted earlier, the ASTM polyiso specification requires that the value at 75°F must be published and that values at 40 and 110°F be available on request. The mean reference temperatures for the ASHRAE Climate Zones for winter and summer conditions, assuming an indoor design temperature of 68°F are shown here:

- From the data, it's clear that the R-value reported for a mean temperature of 75°F is appropriate for summer, and in many cases, for winter.

- Building design professionals designing roofs for ASHRAE climate zones 6 and 7 may need to use the R-value reported for a mean temperature of 40°F when evaluating winter heating requirements.

Also, electricity costs are about four times the cost of natural gas on a British Thermal Unit of energy equivalent basis. When specifying insulation, if gas heat is being used then summer air conditioning costs could dominate and the R-value at the 75°F mean temperature could be the most important.

The "R-Value Rule"

While knowledge of a material's R-value is important to the commercial building market for the HVAC specifier and building owners/occupiers, home owners and individual consumers are generally unable to verify claims as to the thermal resistance. In the aftermath of the 1970's energy crisis, fraudulent R-value claims became so widespread the US Congress passed a consumer-protection law in response, the "R-Value Rule". The R-Value Rule "requires home insulation manufacturers, professional installers, new home sellers, and retailers to provide R-value information, based on the results of standard tests."

Polyiso is used as continuous insulation in residential wall systems and roof assemblies in many apartment and high rise condominium buildings. It is unfeasible for polyiso manufacturers to differentiate between products going into residential versus commercial applications. Therefore, in practice the R-Value Rule covers all polyiso meaning that labeled R-values are legally enforceable.

Conclusions

- Thermal conductivity of polyiso, in common with most other foams, is dominated by the thermal conduction of the cell gases.

- Contrary to popular understanding, R-values are reported as an average across a temperature range and do not represent a value at an exact temperature. For example, the reported R-value at 75°F is normally measured across a range from 50 to 100°F and should be noted as a mean R-value.

- Building designers and specifiers are advised to use the labelled R-values shown for a mean temperature of 75°F. For projects in ASHRAE climate zones 6 and 7, values at 40F °could be used depending on the building's geometry and local energy costs.

Want to learn more? See my recent article in Interface.