Understanding your attic ventilation options can lead to higher quality roof system installations, which in turn boosts your business and helps keep your customers happy. Sounds like an all-around win, right? Fortunately, installing the right attic ventilation options can be a bit simpler when you know how to calculate the proper amount of ventilation and choose the right products for the job.

Installing effective ventilation—and helping your customers understand what you're doing—can also build trust and respect among your customers. When you talk about proper attic ventilation, you differentiate yourself from your competitors. Instead of dropping off a shingle sample board and a quote with the customer, you can raise the bar by teaching your customer about other important parts of a roofing system.

When it comes to your attic ventilation options, here are some key things you should know.

Why Attic Ventilation Is Important

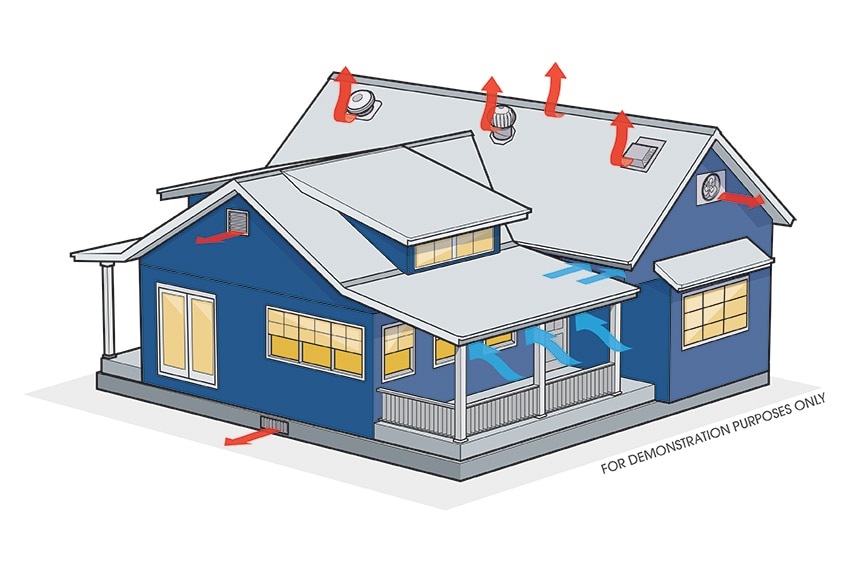

A properly ventilated attic allows air to flow in at the lowest point and escape at the highest point. Ventilation helps protect the roof system from the inside out in virtually all climates and weather conditions.

To help your customers understand how important attic ventilation is, consider touching on the following talking points:

Energy efficiency: Excessive heat in an unventilated attic may cause your AC unit to work overtime and contribute to increased energy costs. Proper attic ventilation can help promote the home's energy efficiency by allowing convection to do some of the work instead. Cooler, dry air pushes out excessive heat and moisture.

Moisture Damage: Without the flow of drier outside air through the attic, condensation and moisture can collect in attics and lead to all kinds of problems. Mold can flourish in unventilated areas. Insulation impacted by moisture may lose R-value—again potentially impacting energy bills. Moisture and condensation can lead to potential damage to roofing products and structural supports.

Ice Damming: Without proper ventilation, heat from the home's interior can collect in the attic and, in conjunction with the sun, can melt the snow on the roof. The melted snow flows down to the lower portion of the roof, then freezes again at night as the exterior temperature drops. This cycle of freeze and thaw can cause ice to back up under the shingles, which can damage the roof system and lead to expensive interior damage such as stained interior drywall and wet insulation. Proper ventilation allows cool exterior air into the attic to reduce that interior heat build-up, which in turn helps to reduce the melting and freezing cycle that typically causes ice damming.

How to Calculate Ventilation

Use this quick, three-step process to find the right attic ventilation for each house.

Measure the attic floor space (L x W) of the area to be ventilated. Get inside the attic; don't just use the roof plane as the basis for measurement.

Calculate the total attic ventilation needed with the easy-to-use 1:300 rule. Install a minimum of 1 square foot of attic ventilation for every 300 square feet of attic floor space being ventilated when using soffit to ridge venting, per the U.S. Federal Housing Authority. This online ventilation calculator does the math for you.

Divide the total ventilation needed in half. One half will be exhaust ventilation, and the other half will be intake ventilation. It's crucial that exhaust and intake be evenly split (commonly referred to as a balanced system)—otherwise, the system can be rendered ineffective. Unfortunately, many times intake ventilation is overlooked, whether due to a lack of soffits, complicated roof design, or simply because you just didn't think about it.

How to Choose Attic Ventilation Options

An industry leader installs ventilation products tailored to the customer's roof style, architecture, and regional climate—not just what's cheapest and easiest.

Exhaust Ventilation

Install exhaust ventilation at the highest roof point to move as much hot, moist air out of the attic as possible. Ridge vents, like those in the GAF Cobra® product line, are typically installed at the ridge or peak of the roof to move hot air out. There are also various off-ridge exhaust options, like the GAF Master Flow® product line, for modern roof designs with limited ridge. These options include power attic vents, roof louvers, and wind turbines.

Intake Ventilation

Intake ventilation is installed at the lowest portion of the roof to allow cooler, drier outside air to push warm, moist attic air up and out of exhaust vents. Remember, the exhaust ventilation needs the intake ventilation for the system to be effective. Intake ventilation includes soffit and undereave vents, like those in the GAF Master Flow® product line.

Installing intake ventilation may often require you to collaborate with other trades like siding or carpenters to ensure proper intake ventilation is installed. You may even have to make sure the painter hasn't painted over the intake vents at the eaves and that they are clear of any attic insulation or debris. If coordinating with the other trades simply isn't an option, or you're doing a re-roofing job, check out Cobra IntakePro®, an intake vent that keeps roofers on the roof. Similar to a ridge vent, an air slot is cut into the lower portion of the roof deck to allow a continuous flow of intake air into the attic.

Climate-Appropriate Ventilation Products

Installing the right products for the region's climate so that the ventilation system runs at peak performance is key. For example, a product like Cobra® SnowCountry® features an internal snow filter for colder, snow-prone environments. Even without the risk of regular snowfall, it's always smart to use a filtered ridge vent in colder climates or those in higher altitudes.

On the other hand, the Cobra® Rigid Vent 3™ is designed specifically for handling attic ventilation in warmer climates. The right roofing products work with proper attic ventilation options to help keep roofing systems healthy and balanced. This vent is not only designed to allow heat and moisture to escape the attic, it also helps resist wind-driven rain infiltration.

GAF offers a broad line of attic ventilation products including ridge, hip, intake, power, and other off-ridge ventilation solutions for use on virtually any roof design and in any climate. Installing the right ventilation products in a properly balanced system helps to keep your customers' roof systems functioning properly for years to come.

Continue to elevate your roofing knowledge and business skills through online education with the experts at the GAF Learning Portal. (If you're accessing the Learning Portal for the first time, use Branch code: GAF when registering.)