Ventilation Calculator

How to Calculate

Step 1: Measure

Step 2: Calculate

Step 3: Identify

Let’s get started

Use this calculator to help determine the proper amount of attic ventilation based on U.S. FHA 1/300 guidelines.*

Suggestions for 900 sq. ft. Area

Please Note:

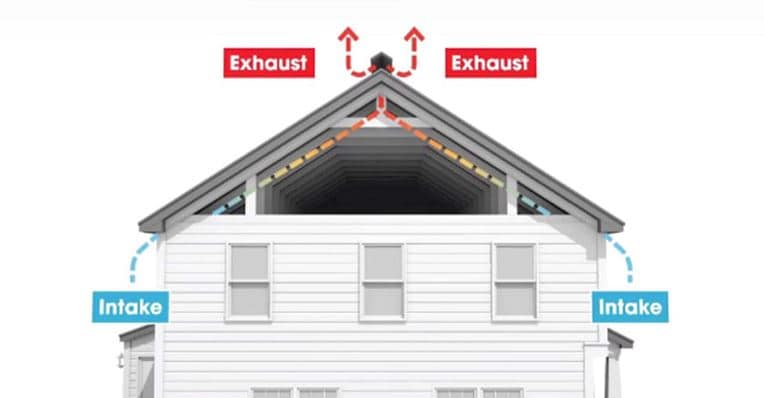

Exhaust Ventilation

| Product | Lineal Feet Required |

|---|---|

| Cobra® RidgeRunner® | 31' |

| Cobra® Rigid Vent 3™ | 22' |

| Cobra® SnowCountry® | 22' |

| Cobra® SnowCountry® Advanced | 22' |

| Cobra® Hip Vent | 43' |

| TruSlate® Ridge Vent | 43' |

Product

Cobra® RidgeRunner®

Lineal Feet Required

31'

Product

Cobra® Rigid Vent 3™

Lineal Feet Required

22'

Product

Cobra® SnowCountry®

Lineal Feet Required

22'

Product

Cobra® SnowCountry® Advanced

Lineal Feet Required

22'

Product

Cobra® Hip Vent

Lineal Feet Required

22'

Product

TruSlate® Ridge Vent

Lineal Feet Required

22'

| Product | Lineal Feet Required |

|---|---|

| Cobra® Exhaust Vent - Hand Nailable | 31' |

| Cobra® Exhaust Vent - Nail Gunnable | 22' |

Product

Cobra® Exhaust Vent - Hand Nailable

Lineal Feet Required

31'

Product

Cobra® Exhaust Vent - Nail Gunnable

Lineal Feet Required

22'

| Product | Lineal Feet Required |

|---|---|

| AR10 | 31' |

Product

AR10

Lineal Feet Required

31'

| Product | Number Required |

|---|---|

| RT65 Plastic Square - Top | 31 |

| IR61 Plastic Slant - Back | 31 |

| R50/RV50 Metal Utility | 31 |

| IR65 Plastic Slant - Back | 31 |

| SSB960 Metal Super Slant - Back | 31 |

| HCD144 High-Capacity Dome Vent | 31 |

Product

RT65 Plastic Square - Top

Number Required

31

Product

IR61 Plastic Slant - Back

Number Required

31

Product

R50/RV50 Metal Utility

Number Required

31

Product

IR65 Plastic Slant - Back

Number Required

31

Product

SSB960 Metal Super Slant - Back

Number Required

31

Product

HCD144 High-Capacity Dome Vent

Number Required

31

Intake Ventilation

| Product | Lineal Feet Required |

|---|---|

| Cobra IntakePro® | 31' |

Product

Cobra IntakePro®

Lineal Feet Required

31'

Product

Cobra® Fascia Vent (Mesh Roll) 1"

Lineal Feet Required

22'

Product

Cobra® Fascia Vent (Mesh Roll) 1.5"

Lineal Feet Required

22'

| Product | Number Required |

|---|---|

| LSV8 Metal Continuous Soffit Vents (Lineal Feet) | 31' |

| EAP 4x12 Plastic Soffit Vents | 31 |

| EAC 16x4 Metal Soffit Vents | 31 |

| EAC 16x8 Metal Soffit Vents | 31 |

| EmberShield® Closeable Soffit Vents | 31 |

Product

LSV8 Metal Continuous Soffit Vents

Number Required

31

Product

EAP 4x12 Plastic Soffit Vents

Number Required

22

Product

EAC 16x4 Metal Soffit Vents

Number Required

22

Product

EAC 16x8 Metal Soffit Vents

Number Required

22

Product

EmberShield® Closeable Soffit Vents

Number Required

22

Intake or Exhaust Ventilation

Note: Gable louvers are typically installed in pairs

| Product | Number Required |

|---|---|

| DA 12x12 | 31 |

| DA 12x18 | 31 |

| DA 14x24 | 31 |

| DA 18x24 | 31 |

| DA 24x30 | 31 |

Product

DA 12x12

Number Required

31

Product

DA 12x18

Number Required

31

Product

DA 14x24

Number Required

31

Product

DA 18x24

Number Required

32

Product

DA 24x30

Number Required

33

| Product | Number Required |

|---|---|

| SL 8x8 | 31 |

| SL 12x12 | 31 |

| SL 12x18 | 31 |

| SL 18x24 | 31 |

Product

SL 8x8

Number Required

34

Product

SL 12x12

Number Required

35

Product

SL 12x18

Number Required

36

Product

SL 14x24

Number Required

37

Product

SL 18x24

Number Required

38

| Product | Number Required |

|---|---|

| RLSC 2" | 31 |

| RLSC 3" | 31 |

| RLSC 4" | 31 |

Product

RLSC 2"

Number Required

39

Product

RLSC 3"

Number Required

40

Product

RLSC 4"

Number Required

41

Exhaust Ventilation

| Product | Number Required |

|---|---|

| ERV4 | 31 |

| ERV5 & Wi-Fi ERV5QCT | 22 |

| ERV6 | 22 |

| EZ Cool™ EZCR1 | 22 |

Product

ERV4

Number Required

31

Product

ERV5 & Wi-Fi ERV5QCT

Number Required

22

Product

ERV6

Number Required

31

Product

EZ Cool™ EZCR1

Number Required

31

| Product | Number Required |

|---|---|

| EGV5 & Wi-Fi EGV5QCT | 31 |

| EGV6 | 22 |

| EZ Cool™ EZCG1 | 22 |

Product

EGV5 & Wi-Fi EGV5QCT

Number Required

31

Product

EGV6

Number Required

31

Product

EZ Cool™ EZCG1

Number Required

31

| Product | Number Required |

|---|---|

| Solar & Dual-Powered Roof (ERVSOLAR / ERVHYBRID) | 31 |

| Solar-Powered Gable (PGSOLAR) | 22 |

| High-Power Solar & Dual-Powered Roof (PRSOLAR2 / PRHYBRID2) | 22 |

Product

Solar & Dual-Powered Roof (ERVSOLAR / ERVHYBRID)

Number Required

31

Product

Solar-Powered Gable (PGSOLAR)

Number Required

31

Product

High-Power Solar & Dual-Powered Roof (PRSOLAR2 / PRHYBRID2)

Number Required

31

| Product | Number Required |

|---|---|

| 12" | 31 |

| 14" | 22 |

Product

12"

Number Required

31

Product

14"

Number Required

31

Intake Ventilation

| Product | Lineal Feet Required |

|---|---|

| with ERV4 | 31' |

| with ERV5 & Wi-Fi ERV5QCT | 22' |

| with ERV6 | 31' |

| with EZ Cool™ EZCR1 | 31' |

| with EGV5 & Wi-Fi EGV5QCT | 22' |

| with EGV6 | 31' |

| with EZ Cool™ EZCG1 | 31' |

| with Solar & Dual-Powered Roof | 22' |

| with Solar-Powered Gable | 22' |

| with High-Power Solar & Dual-Powered Roof | 22' |

| with 12" Wind Turbine | 22' |

| with 14" Wind Turbine | 22' |

Product

with ERV4

Lineal Feet Required

31'

Product

with ERV5 & Wi-Fi ERV5QCT

Lineal Feet Required

31'

Product

with ERV6

Lineal Feet Required

31'

Product

with EZ Cool™ EZCR1

Lineal Feet Required

31'

Product

with EGV5 & Wi-Fi EGV5QCT

Lineal Feet Required

31'

Product

with EGV6

Lineal Feet Required

31'

Product

with EZ Cool™ EZCG1

Lineal Feet Required

31'

Product

with Solar & Dual-Powered Roof

Lineal Feet Required

31'

Product

with Solar-Powered Gable

Lineal Feet Required

31'

Product

with High-Power Solar & Dual-Powered Roof

Lineal Feet Required

31'

Product

with 12" Wind Turbine

Lineal Feet Required

31'

Product

with 14" Wind Turbine

Lineal Feet Required

31'

| Product | Lineal Feet Required |

|---|---|

| with ERV4 | 31' |

| with ERV5 & Wi-Fi ERV5QCT | 22' |

| with ERV6 | 31' |

| with EZ Cool™ EZCR1 | 31' |

| with EGV5 & Wi-Fi EGV5QCT | 22' |

| with EGV6 | 31' |

| with EZ Cool™ EZCG1 | 31' |

| with Solar & Dual-Powered Roof | 22' |

| with Solar-Powered Gable | 22' |

| with High-Power Solar & Dual-Powered Roof | 22' |

| with 12" Wind Turbine | 22' |

| with 14" Wind Turbine | 22' |

Product

with ERV4

Lineal Feet Required

31'

Product

with ERV5 & Wi-Fi ERV5QCT

Lineal Feet Required

31'

Product

with ERV6

Lineal Feet Required

31'

Product

with EZ Cool™ EZCR1

Lineal Feet Required

31'

Product

with EGV5 & Wi-Fi EGV5QCT

Lineal Feet Required

31'

Product

with EGV6

Lineal Feet Required

31'

Product

with EZ Cool™ EZCG1

Lineal Feet Required

31'

Product

with Solar & Dual-Powered Roof

Lineal Feet Required

31'

Product

with Solar-Powered Gable

Lineal Feet Required

40'

Product

with High-Power Solar & Dual-Powered Roof

Lineal Feet Required

31'

Product

with 12" Wind Turbine

Lineal Feet Required

31'

Product

with 14" Wind Turbine

Lineal Feet Required

31'

| Product | Number Required |

|---|---|

| with ERV4 | 31 |

| with ERV5 & Wi-Fi ERV5QCT | 22 |

| with ERV6 | 31 |

| with EZ Cool™ EZCR1 | 31 |

| with EGV5 & Wi-Fi EGV5QCT | 22 |

| with EGV6 | 31 |

| with EZ Cool™ EZCG1 | 31 |

| with Solar & Dual-Powered Roof | 22 |

| with Solar-Powered Gable | 22 |

| with High-Power Solar & Dual-Powered Roof | 22 |

| with 12" Wind Turbine | 22 |

| with 14" Wind Turbine | 22 |

Product

with ERV4

Number Required

31

Product

with ERV5 & Wi-Fi ERV5QCT

Number Required

31

Product

with ERV6

Number Required

31

Product

with EZ Cool™ EZCR1

Number Required

31

Product

with EGV5 & Wi-Fi EGV5QCT

Number Required

31

Product

with EGV6

Number Required

31

Product

with EZ Cool™ EZCG1

Number Required

31

Product

with Solar & Dual-Powered Roof

Number Required

31

Product

with Solar-Powered Gable

Number Required

49

Product

with High-Power Solar & Dual-Powered Roof

Number Required

31

Product

with 12" Wind Turbine

Number Required

31

Product

with 14" Wind Turbine

Number Required

31

| Product | Number Required |

|---|---|

| with ERV4 | 31 |

| with ERV5 & Wi-Fi ERV5QCT | 22 |

| with ERV6 | 31 |

| with EZ Cool™ EZCR1 | 31 |

| with EGV5 & Wi-Fi EGV5QCT | 22 |

| with EGV6 | 31 |

| with EZ Cool™ EZCG1 | 31 |

| with Solar & Dual-Powered Roof | 22 |

| with Solar-Powered Gable | 22 |

| with High-Power Solar & Dual-Powered Roof | 22 |

| with 12" Wind Turbine | 22 |

| with 14" Wind Turbine | 22 |

Product

with ERV4

Number Required

31

Product

with ERV5 & Wi-Fi ERV5QCT

Number Required

31

Product

with ERV6

Number Required

31

Product

with EZ Cool™ EZCR1

Number Required

31

Product

with EGV5 & Wi-Fi EGV5QCT

Number Required

31

Product

with EGV6

Number Required

31

Product

with EZ Cool™ EZCG1

Number Required

31

Product

with Solar & Dual-Powered Roof

Number Required

31

Product

with Solar-Powered Gable

Number Required

58

Product

with High-Power Solar & Dual-Powered Roof

Number Required

31

Product

with 12" Wind Turbine

Number Required

31

Product

with 14" Wind Turbine

Number Required

31

| Product | Number Required |

|---|---|

| with ERV4 | 31 |

| with ERV5 & Wi-Fi ERV5QCT | 22 |

| with ERV6 | 31 |

| with EZ Cool™ EZCR1 | 31 |

| with EGV5 & Wi-Fi EGV5QCT | 22 |

| with EGV6 | 31 |

| with EZ Cool™ EZCG1 | 31 |

| with Solar & Dual-Powered Roof | 22 |

| with Solar-Powered Gable | 22 |

| with High-Power Solar & Dual-Powered Roof | 22 |

| with 12" Wind Turbine | 22 |

| with 14" Wind Turbine | 22 |

Product

with ERV4

Number Required

31

Product

with ERV5 & Wi-Fi ERV5QCT

Number Required

31

with ERV6

Number Required

31

with EZ Cool™ EZCR1

Number Required

31

with EGV5 & Wi-Fi EGV5QCT

Number Required

31

with EZ Cool™ EZCG1

Number Required

31

with Solar & Dual-Powered Roof

Number Required

31

with Solar-Powered Gable

Number Required

67

with High-Power Solar & Dual-Powered Roof

Number Required

31

with 12" Wind Turbine

Number Required

31

with 14" Wind Turbine

Number Required

31

| Product | Number Required |

|---|---|

| with ERV4 | 31 |

| with ERV5 & Wi-Fi ERV5QCT | 22 |

| with ERV6 | 31 |

| with EZ Cool™ EZCR1 | 31 |

| with EGV5 & Wi-Fi EGV5QCT | 22 |

| with EGV6 | 31 |

| with EZ Cool™ EZCG1 | 31 |

| with Solar & Dual-Powered Roof | 22 |

| with Solar-Powered Gable | 22 |

| with High-Power Solar & Dual-Powered Roof | 22 |

| with 12" Wind Turbine | 22 |

| with 14" Wind Turbine | 22 |

Product

with ERV4

Number Required

31

Product

with ERV5 & Wi-Fi ERV5QCT

Number Required

31

Product

with ERV6

Number Required

31

Product

with EZ Cool™ EZCR1

Number Required

31

Product

with EGV5 & Wi-Fi EGV5QCT

Number Required

31

Product

with EGV6

Number Required

31

Product

with EZ Cool™ EZCG1

Number Required

31

Product

with Solar & Dual-Powered Roof

Number Required

31

Product

with Solar-Powered Gable

Number Required

75

Product

with High-Power Solar & Dual-Powered Roof

Number Required

31

Product

with 12" Wind Turbine

Number Required

31

Product

with 14" Wind Turbine

Number Required

31

Attic ventilation & vent products

To find the right attic ventilation solution for your roofing project, choose from a complete line of ridge and hip vents, electric and solar power vents, roof and gable louvers, wind turbines, intake vents, and more, all from GAF.

The 1/300 balanced attic ventilation rule

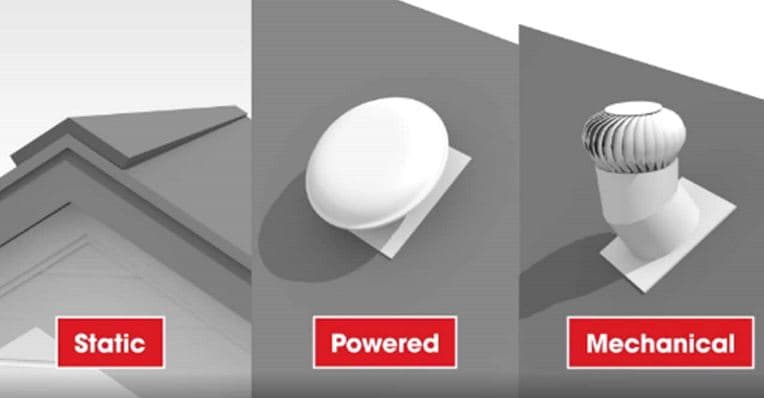

Learn about attic vent options

Your top attic ventilation questions answered

.jpg?as=0&w=510&hash=DC23D30D23AAE7357E4D1AD84F32C60C)

How to Ventilate an Attic - How Attic Ventilation Works | GAF Roofing

How to Select Products for Your Attic Ventilation System | GAF Roofing

How to Plan a Balanced Attic Ventilation System | GAF Roofing Materials